ABOUT TUBTARA®

More than 70 years ago, our development and production of blind rivet nuts started in Antwerp. And our Tubtara® division was born. We are still a pioneer with a long tradition of innovation. We use our in-depth knowledge of materials and coldforming production processes to create a future-proof product portfolio tailored to your needs.

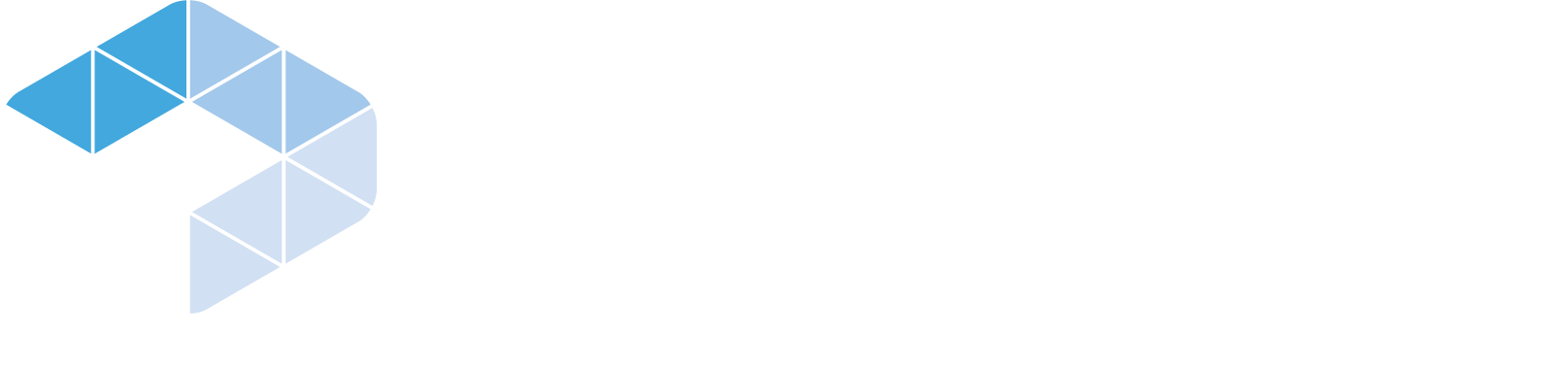

What are Tubtara® Blind Rivet Nuts?

A Tubtara® blind rivet nut is a mechanical fastener that ensures a strong thread in:

- Thin metal plates/profiles: no thread forming possible

- Thick metal plates/profiles: too hard for thread forming or on site repair

- Composites or plastics: no thread forming possible

Blind

- You install the Tubtara® from one side of the workpiece

- This is useful in applications where there is little or no access from/at the rear

- Ideal for use in boxed or enclosed applications

Rivet

- The Tubtara® can clinch separate sheets together (therefore acting as a rivet)

Nut

- The Tubtara® provides a strong thread in a plate or profile

- Enabling the assembly of other components via a bolt or screw

Tubtara® blind rivet nuts are used in all kinds of sheet metal and composite applications. They eliminate the need for tapping, welding or working with nuts and bolts. As such, they form an ideal solution for enclosed applications that can only be accessed from one side.

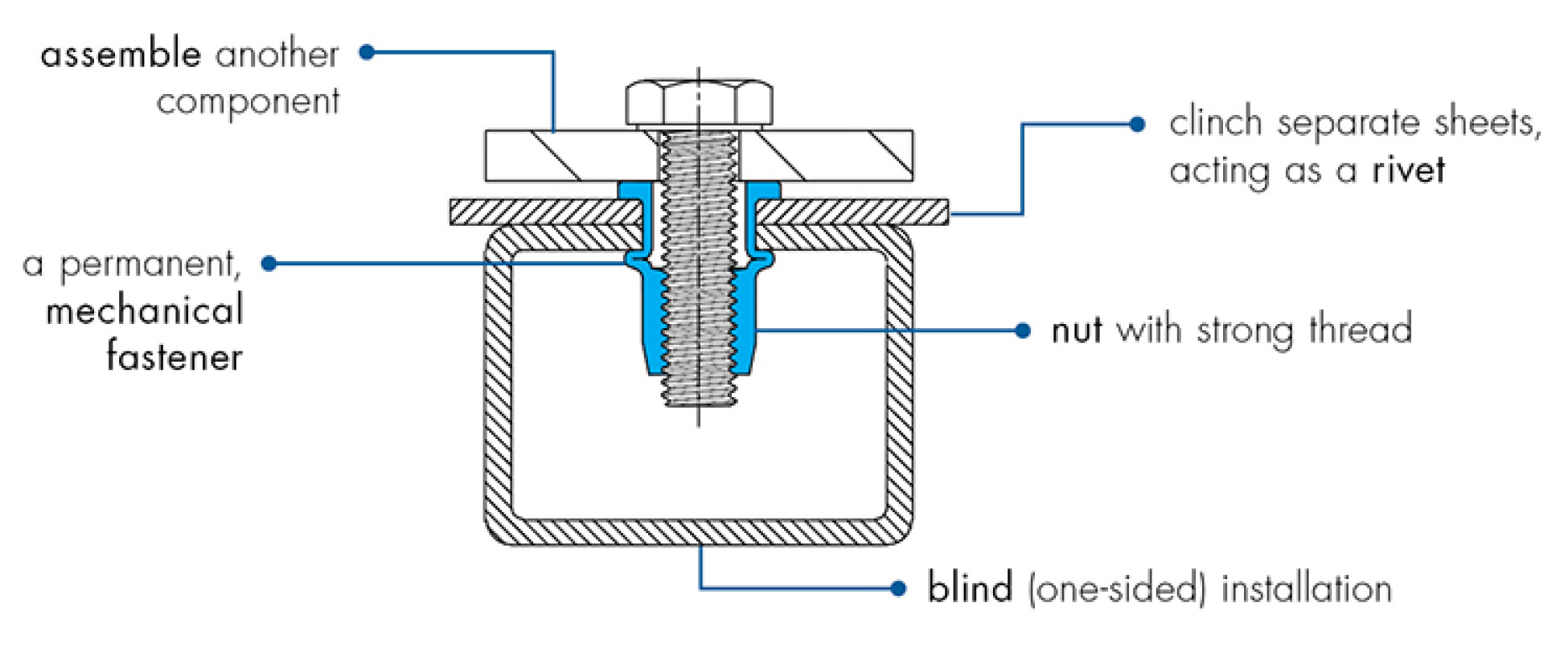

Terminology

|

|

Product description

| Steel | M5 | RS | UFO | 40 |

| Stainless | M10 | H | SPX | 35 |

| Aluminium | M8 | - | UPO | 80 |

| Steel | M6 | - | DPX | 50 |

| Steel | M4 | KN | UKO | 30 |

material |

thread |

shank |

head & shank |

max grip |

| RS: splined | U / S: Unigrip | 40 = 4 mm | ||

| H: hexagonal | D: Sealed | 35 = 3,5 mm | ||

| KN: knurled | F: countersunk head | 80 = 8 mm | ||

| -: round | P: flat head | 50 = 5 mm | ||

| K: low profile head | 30 = 3 mm | |||

| O: open end | ||||

| X: closed end |

The benefits of Tubtara® Blind Rivet Nuts

Tubtara® blind rivet nuts are a very good solution for enclosed applications that can only be accessed from one side.

Discover the 10 reasons why you should choose Tubtara® blind rivet nuts.

- Simple blind installation: applied from one side of the workpiece

- Low assembly cost: versus other methods of installing threads in plates or profiles

- Fast, easy assembly: further reducing the assembly cost

- Zero-risk installation: no damage to the workpiece surface, enabling installation in pre-coated or pre-painted applications for a clean, undamaged thread

- No deformation of the workpiece

- No surface preparation required

- Ideal for close-to-edge applications

- Suitable for repeated assembly

- Retained fastener: cf. machinery directive 2006/42/EC

- Low installation cost: no expensive tools or equipment required

How to choose the right Tubtara®?

- What kind of material and surface treatment do you need?

- What is the required thread size?

- Choose the correct grip range for the required material thickness.

- Choose the required head and shank style.

- Do you need an open or closed-end version?

- Check the technical characteristics of your chosen Tubtara®.

Easy installation

Installing a Tubtara® blind rivet nut is very simple.

Select one of the Tubtara® blind rivet nuts from our extensive product range and a matching setting tool. Take a test workpiece and drill an appropriate hole.

|

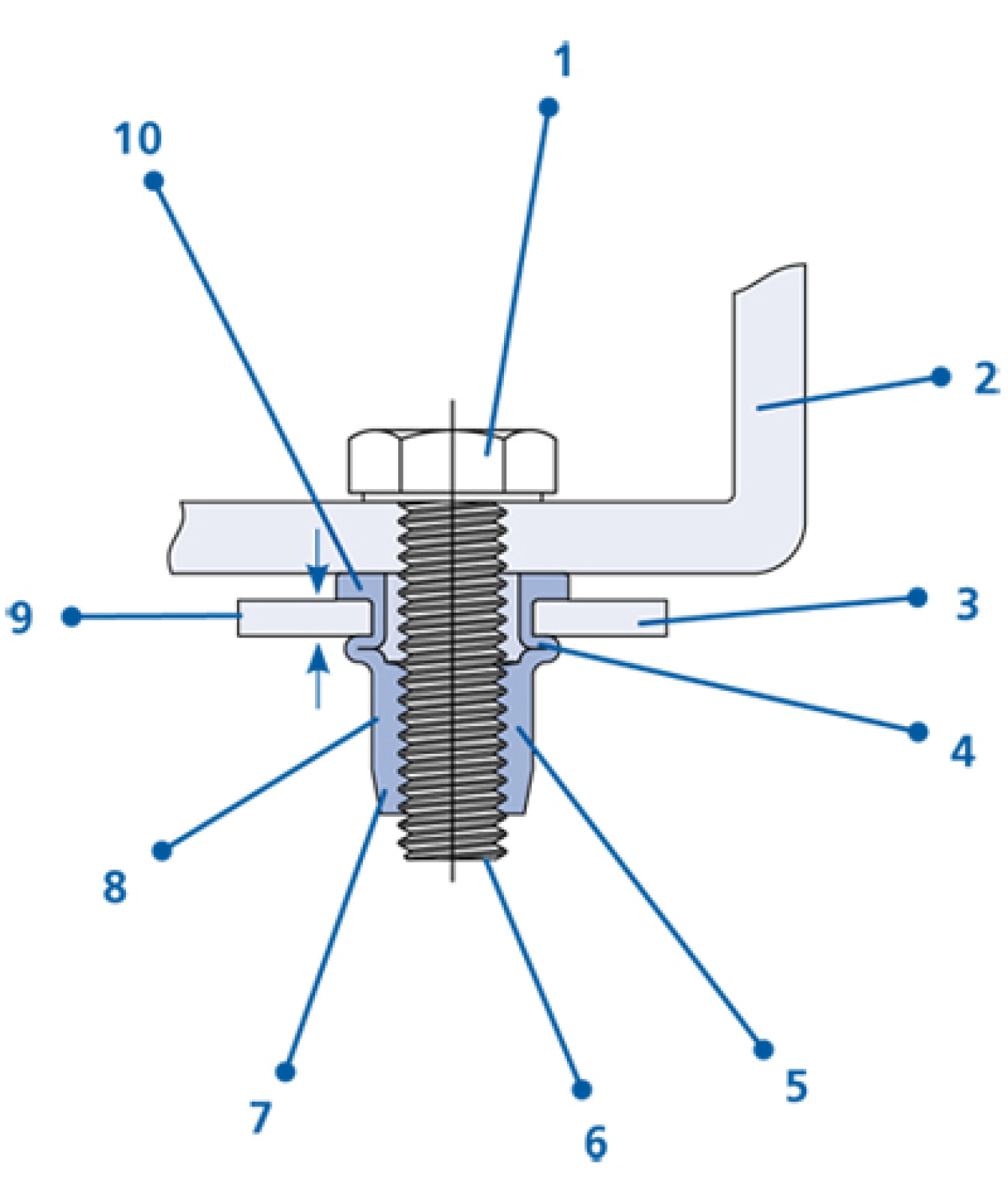

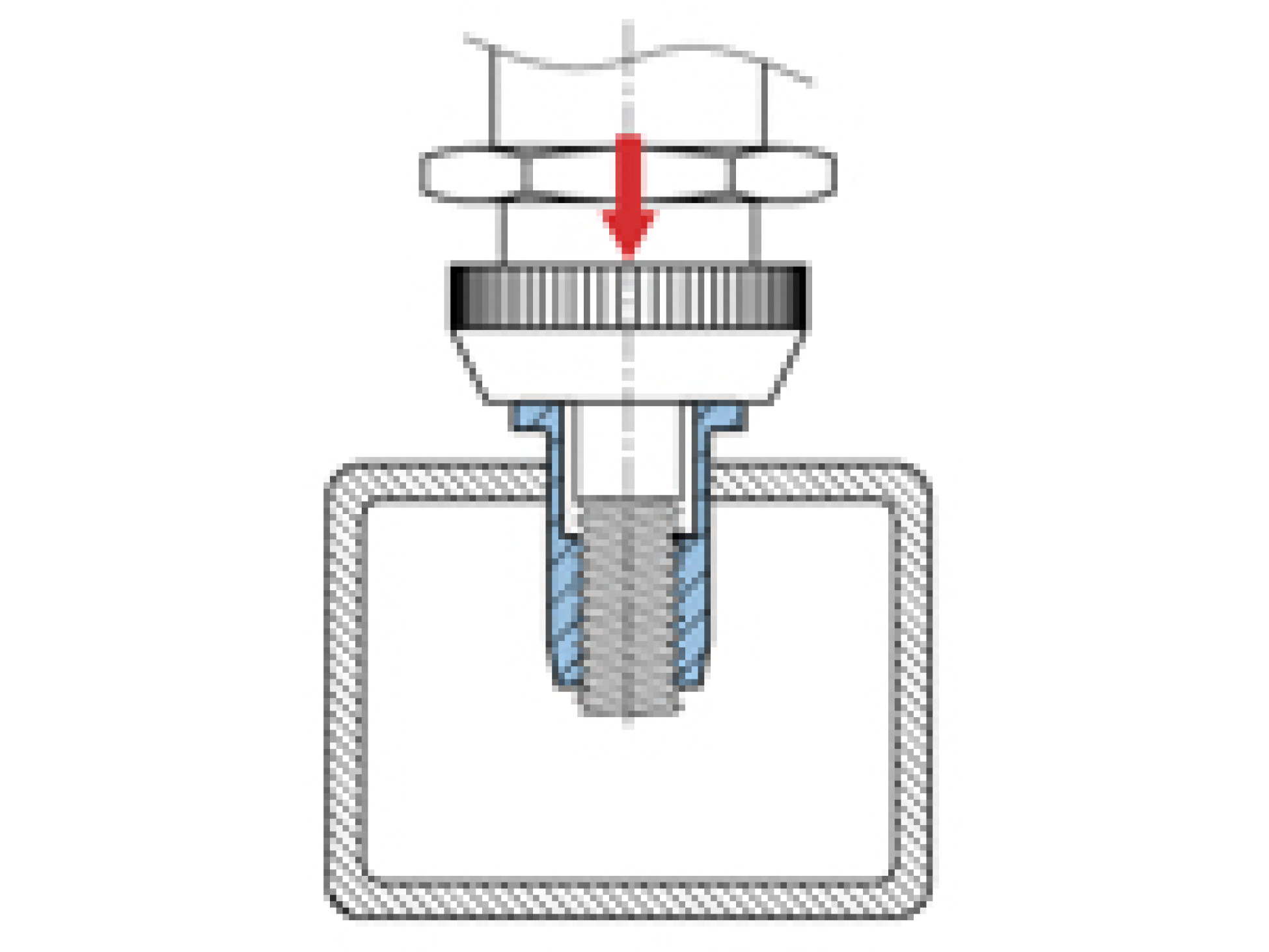

STEP 1 Screw the Tubtara® blind rivet nut (A) on the mandrel (B) of the setting tool. In the case of the open version, the mandrel should protrude about 1 mm. For closed rivet nuts, continue screwing until you feel resistance. Screw the anvil (C) against the head of the Tubtara® and block it with the locking nut (D). |

|

|

STEP 2 Insert the Tubtara® blind rivet nut, mounted on the setting tool, into the hole of the workpiece. |

|

|

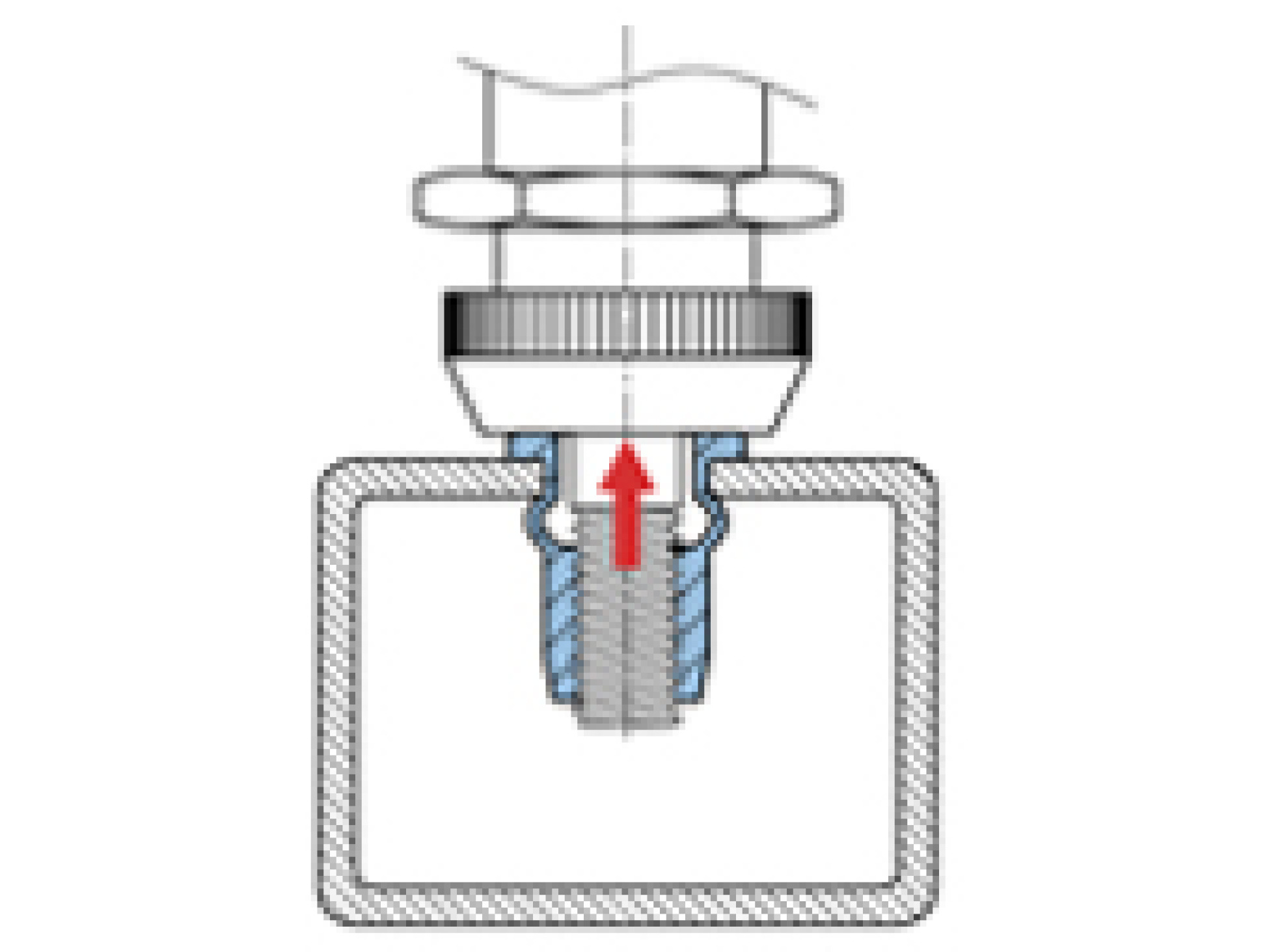

STEP 3 Set the Tubtara®. The Tubtara’s deformation chamber now forms the counter head (bulb) on the underside of the workpiece. |

|

|

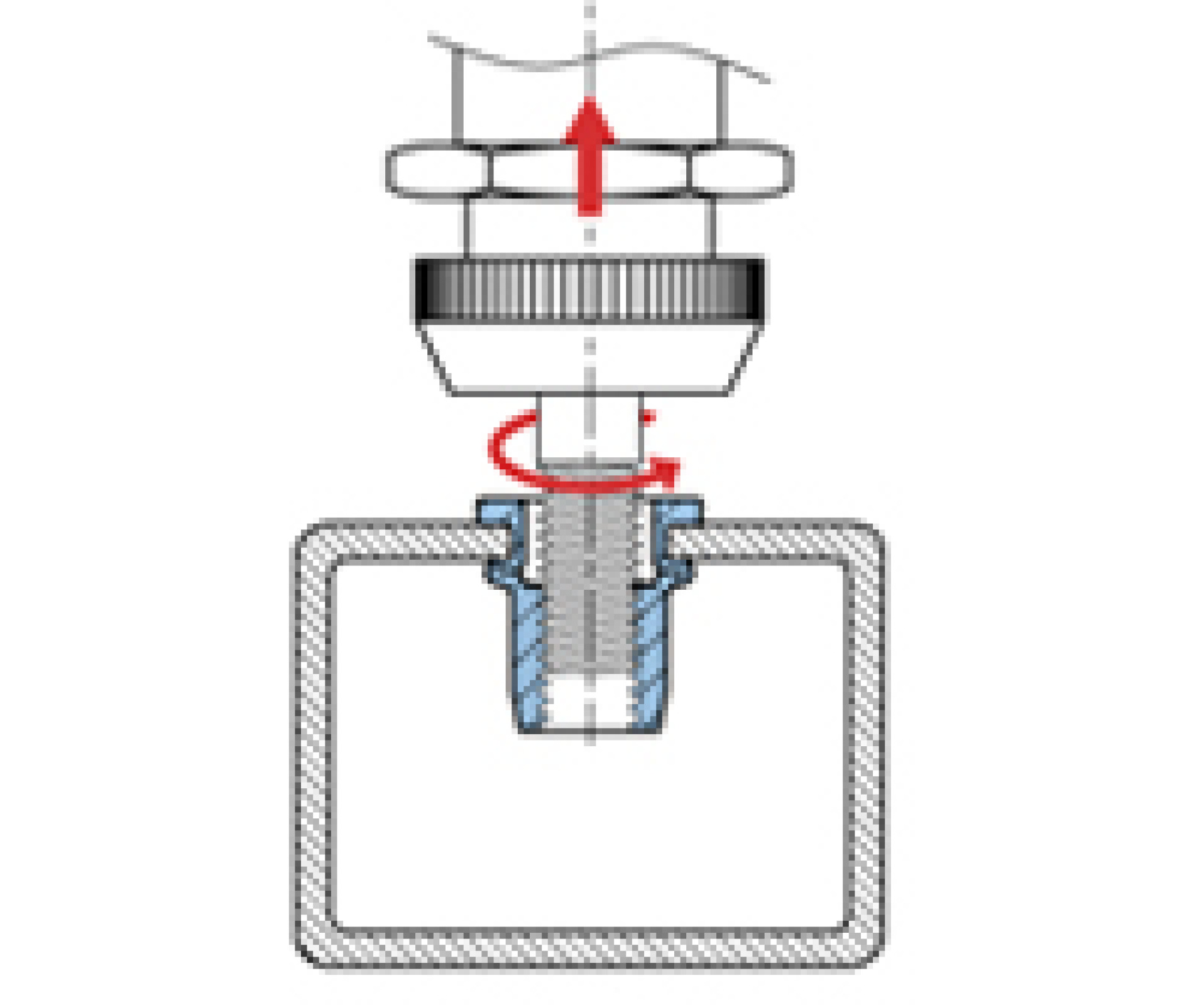

STEP 4 Unscrew the mandrel from the Tubtara®. |

|

|

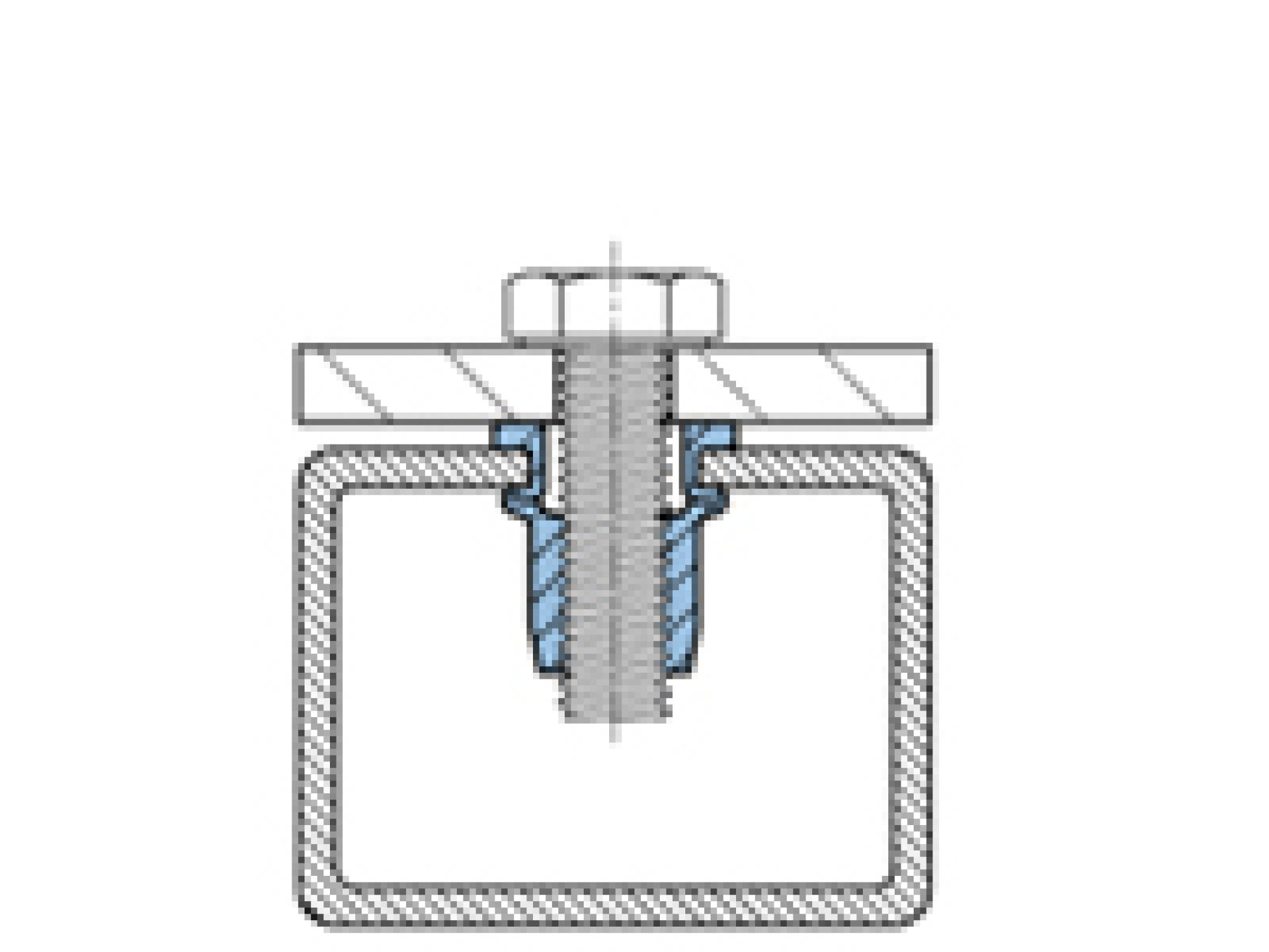

STEP 5 The Tubtara® blind rivet nut is now set. You can now easily insert your bolt or screw to assemble another component. |

|

Countersunk heads

Are you using a Tubtara® blind rivet nut with a countersunk head? Always countersink at 90° so that the head of the installed Tubtara® protrudes about 0.1 mm above your workpiece. This ensures direct contact with the assembled component.

Don’t have the possibility to countersink? Use a low profile head.

Setting dangers

- Oversized hole (can affect setting & torque-to-turn)

- Burr under the hole (can impact grip range)

- Oiled/dirty hole (can affect torque-to-turn)

- Incorrect hole shape for countersunk head (tightening bolt will loosen the Tubtara® blind fastener)

Markets & applications

Tubtara® blind rivet nuts are used in all kinds of demanding environments. From the aerospace industry to the automotive, electronics, railways, marine, offshore, medical and food industries. The cases illustrate the proven performance of the Tubtara® blind rivet nuts and fastening systems in a wide range of applications, such as cabinets, pipes, cable trays, leg levelling, window and door profiles, rails, benches, fences, metal enclosures, heating installations, air conditioning, swimming pools, solar panels, etc.

| Aerospace | Automotive | Chemical | Construction |

| Electronics | Food | Lighting | Marine |

| Medical | Metal furniture | Offshore | Pulp & Paper |

| Railways | Road infrastructure | Solar panels | Telecom |

| White goods |